I-Driverless Electric Locomotive System

Isixazululo Sesendlalelo Sesistimu Yokuthutha Ithrekhi Engenamuntu

Njengamanje, uhlelo lwezokuthutha lukaloliwe olungaphansi komhlaba lwasekhaya luqhutshwa futhi lusetshenziswa abasebenzi baseposini esizeni.Isitimela ngasinye sidinga umshayeli nesisebenzi sasemayini, futhi inqubo yokuthola indawo, ukulayisha, ukushayela nokudweba ingaqedwa ngokusebenzisana kwabo bobabili.Ngaphansi kwalesi simo, kulula ukubangela izinkinga ezifana nokusebenza kahle kokulayisha okuphansi, ukulayisha okungavamile kanye nezingozi ezinkulu zokuphepha ezingaba khona.Uhlelo lokulawula ezokuthutha lukaloliwe olungaphansi komhlaba lwaqala ukuvela phesheya ngeminyaka yawo-1970.I-Kiruna Underground Iron Mine eSweden yaqala yathuthukisa izitimela ezilawula kude ezingenazintambo kanye nobuchwepheshe bokuxhumana obungenantambo, futhi yabona ngempumelelo isilawuli kude esingenantambo sezitimela ezingaphansi komhlaba.Kuyo yonke iminyaka emithathu ezimele yocwaningo nokuthuthukiswa kanye nokuhlolwa kwendawo, i-Beijing Soly Technology Co., Ltd. ekugcineni ibeke uhlelo oluzenzakalelayo lokugijima kwesitimela ku-inthanethi ngoNovemba 7, 2013 e-Xingshan Iron Mine yeShougang Mining Company.Ilokhu isebenza ngokuzinzile kuze kube manje.Lolu hlelo lubona ngempumelelo ukuthi abasebenzi bangasebenza esikhungweni sokulawula umhlabathi esikhundleni sokusebenza ngaphansi komhlaba, futhi libona ukusebenza okuzenzakalelayo kohlelo lokuthutha izitimela ezingaphansi komhlaba, futhi bathole impumelelo elandelayo:

Ukubona ukusebenza okuzenzakalelayo kohlelo lokuthuthwa kwesitimela esingaphansi komhlaba;

Ngo-2013, yabona uhlelo lokulawula isitimela sikagesi esikude ezingeni lama-180m eMayini Yensimbi ye-Xingshan, futhi yazuza umklomelo wokuqala wesayensi yezimayini yezimayini nobuchwepheshe;

Ufake isicelo futhi wathola ilungelo lobunikazi ngo-2014;

Ngo-May 2014, iphrojekthi yaphasisa iqoqo lokuqala lokubonisa ukwamukelwa kobunjiniyela be-Safety Technology "amaqoqo amane" we-State Administration for Safety Management and Control.

Isixazululo

Isixazululo sokusebenza okuzenzakalelayo sohlelo lwezokuthutha lukaloliwe olungaphansi komhlaba olwakhiwe yi-Beijing Soly Technology Co., Ltd. sifakelwe isicelo futhi sathola ilungelo lobunikazi futhi siye saqashelwa ngokusemthethweni iminyango kazwelonke efanele, okwanele ukufakazela ukuthi lolu hlelo luhlanganisa ngempumelelo izinhlelo zokuxhumana. , amasistimu ezishintshayo, amasistimu enethiwekhi, amasistimu emishini, isistimu kagesi, isistimu yokulawula kude kanye nesistimu yesignali.Umyalo wokusebenza kwesitimela wenziwa ngendlela efanele yokushayela kanye nendlela yokubala yezindleko, ethuthukisa kakhulu izinga lokusebenzisa, umthamo kanye nokuphepha kukajantshi wesitimela.Ukuma kwesitimela okunembayo kufinyelelwa ngama-odometers, iziqondiso zokubeka indawo kanye nama-speedometer.Isistimu yokulawula isitimela (i-SLJC) kanye nesistimu evaliwe yesignali emaphakathi esekelwe ohlelweni lokuxhumana okungenantambo qaphela ukusebenza okuzenzakalelayo ngokugcwele kwezinto zokuhamba ezihamba ngaphansi komhlaba.Uhlelo oludidiyelwe nohlelo lokuqala lwezokuthutha emayini, lunokunwebeka, oluhlangabezana nezidingo zamakhasimende ahlukene, futhi lufanele izimayini ezingaphansi komhlaba ezinokuthutha ngesitimela.

Ukwakhiwa kwesistimu

Uhlelo luqukethe ukuthunyelwa kwesitimela kanye neyunithi yokulinganisa insimbi (uhlelo lokusabalalisa insimbi yedijithali, uhlelo lokuthunyelwa kwesitimela), iyunithi yesitimela (uhlelo lokuthutha lwesitimela esingaphansi komhlaba, uhlelo lokuvikela isitimela oluzenzakalelayo), iyunithi yokusebenza (isistimu evaliwe yesignali engaphansi komhlaba, uhlelo lwekhonsoli yokusebenza, ukuxhumana okungenantambo. isistimu), iyunithi yokulayisha i-ore (isistimu yokulayisha i-chute ekude, uhlelo lokuqapha ividiyo lokulayisha i-chute ekude), kanye neyunithi yokuthulula (isistimu yesiteshi sokuthulula ngokuzenzakalelayo ngaphansi komhlaba kanye nohlelo lokuhlanza oluzenzakalelayo).

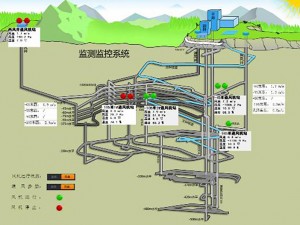

Umfanekiso 1 Umdwebo wokwakheka kwesistimu

Iyunithi yokuthunyelwa kwezitimela kanye ne-ore proportioning unit

Misa uhlelo olufanele lokulinganisa i-ore olugxile ku-chute enkulu.Kusukela esiteshini sokuthulula, ngokulandela isimiso sebanga elizinzile lokuphumayo, ngokuya ngemithombo ye-ore kanye nebanga le-geological ye-chute ngayinye endaweni yezimayini, uhlelo luthumela izitimela ngokwedijithali futhi luxube insimbi;ngokohlelo olufanele lokulinganisa insimbi, isistimu ihlela ngokuqondile uhlelo lokukhiqiza, inquma ukulandelana kokudweba kwensimbi kanye nenani lama-chute ngayinye, futhi inquma izikhawu zokusebenza kanye nomzila wezitimela.

Izinga 1: Ukulinganisa kwensimbi esitobhini, lokho kuyinqubo yokulinganisa i-ore eqala ku-scrapers emba ama-ore bese elahla ama-ore kuya kuma-chute.

Izinga lesi-2: Ukulinganisa kwe-chute eyinhloko, lokho kuyinqubo yokulinganisa insimbi esuka ezitimeleni ezilayisha ama-ore kusuka ku-chute ngayinye bese ethula ama-ore aye e-chute enkulu.

Ngokohlelo lokukhiqiza olulungiswe yipulani ye-ore yezinga lesi-2, isistimu evaliwe yesignali emaphakathi iqondisa isikhawu sokusebenza kanye nezindawo zokulayisha izitimela.Izitimela ezilawulwa kude ziqeda imisebenzi yokukhiqiza ezingeni eliyinhloko lezokuthutha ngokuya ngomzila wokushayela kanye neziqondiso ezinikezwe isistimu evaliwe yesignali emaphakathi.

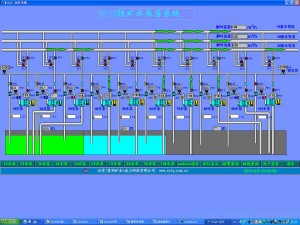

Umfanekiso 2. Umdwebo wohlaka lokuthunyelwa kwesitimela kanye nesistimu yokulinganisa insimbi

Iyunithi yesitimela

Iyunithi yesitimela ihlanganisa uhlelo lokuhamba ngesitimela esingaphansi komhlaba kanye nohlelo lokuvikela isitimela oluzenzakalelayo.Faka isistimu yokulawula izimboni ezizenzakalelayo esitimeleni, engakwazi ukuxhumana nesistimu yokulawula ikhonsoli egumbini lokulawula ngamanethiwekhi angenantambo nanezintambo, futhi wamukele imiyalo ehlukahlukene evela kusistimu yokulawula ikhonsoli, futhi uthumele imininingwane yokusebenza kwesitimela kusilawuli sekhonsoli. uhlelo.Ikhamera yenethiwekhi ifakwe ngaphambili kwesitimela sikagesi esixhumana negumbi lokulawula eliphansi ngenethiwekhi engenantambo, ukuze kubonwe ukuqapha kwevidiyo okukude kwezimo zesitimela.

Iyunithi yokusebenza

Ngokuhlanganiswa kwesistimu evaliwe yesignali emaphakathi, isistimu yokuyala isitimela, uhlelo olunembile lokuthola indawo, uhlelo lokudlulisa ukuxhumana okungenantambo, uhlelo lwevidiyo kanye nesistimu ye-ground console, uhlelo lubona ukusebenza kwesitimela sikagesi esingaphansi komhlaba ngokulawula okukude phansi.

Ukusebenza kwesilawuli kude saphansi:opharetha wesitimela egumbini lokulawula ukhipha isicelo sokulayisha i-ore, i-dispatcher ithumela imiyalelo yokulayisha i-ore ngokusho komsebenzi wokukhiqiza, futhi uhlelo oluvaliwe oluphakathi kwesignali lushintsha ngokuzenzakalelayo amarobhothi ngokuvumelana nezimo zomugqa ngemva kokuthola umyalelo, futhi uqondise isitimela. ku-chute ekhethiwe ukuze ilayishe.Umsebenzisi wesitimela ulawula ukude isitimela ukuze sigijime siye endaweni emisiwe ngesibambo.Uhlelo lunomsebenzi we-speed cruise njalo, futhi u-opharetha angasetha isivinini esihlukile ngezikhathi ezahlukene ukuze anciphise umsebenzi womqhubi.Ngemva kokufinyelela i-chute eqondiwe, u-opharetha ekude uqhuba umdwebo we-ore futhi ahambise isitimela endaweni efanele, aqinisekise ukuthi ubuningi be-ore obulayishiwe buhlangabezana nezidingo zenqubo;ngemva kokuqeda ukulayishwa kwe-ore, faka isicelo sokuthulula, futhi ngemva kokuthola isicelo, isignali yesistimu evaliwe emaphakathi ihlulela ngokuzenzakalelayo izitimela bese iyala isitimela esiteshini sokuthulula ukuze sehlise ama-ore, bese siqedela umjikelezo wokulayisha nokuthulula.

Ukusebenza okuzenzakalelayo ngokugcwele:Ngokolwazi lomyalo oluvela ohlelweni lokulinganiswa kwensimbi yedijithali kanye nokusabalalisa, isistimu evaliwe yesignali emaphakathi iphendula ngokuzenzakalelayo, iyala futhi ilawule izibani zesignali kanye nemishini yokushintsha ukuze yakhe umzila ogijimayo usuka esiteshini sokuthulula uye endaweni yokulayisha, futhi ukusuka endaweni yokulayisha kuye isiteshi sokuthulula.Isitimela sihamba ngokuzenzakalela ngokuzenzakalelayo ngokuya ngolwazi olubanzi nemiyalo ye-ore proportioning kanye nesistimu yokuthunyelwa kwesitimela kanye nesistimu evaliwe yesignali emaphakathi.Lapho sigijima, ngokusekelwe ohlelweni olunembile lokuma kwesitimela, indawo ethile yesitimela iyanqunywa, futhi i-pantograph iphakanyiswa ngokuzenzakalelayo futhi yehliswe ngokuya ngokuma okuqondile kwesitimela, futhi isitimela sihamba ngokuzenzekelayo ngesivinini esinqunyiwe ngezikhawu ezihlukene.

Ilayisha iyunithi

Ngezithombe zevidiyo, u-opharetha usebenzisa uhlelo lokulawula ukulayisha i-ore ukuze abone ukulayishwa kwe-ore ukude egumbini lokulawula phansi.

Lapho isitimela sifika endaweni yokulayisha, u-opharetha ukhetha futhi aqinisekise i-chute edingekayo ngokusebenzisa isibonisi sekhompuyutha esezingeni eliphezulu, ukuze axhumanise ubudlelwano phakathi kwe-chute elawulwayo nohlelo lokulawula phansi, futhi akhiphe imiyalo yokulawula i-chute ekhethiwe.Ngokushintsha isikrini sokuqapha ividiyo sesiphakeli ngasinye, isiphakeli esidlidlizayo kanye nesitimela zisebenza ngendlela ebumbene nedidiyelwe, ukuze kuqedelwe inqubo yokulayisha ukude.

Iyunithi yokulayisha

Ngohlelo lokuthulula nokuhlanza oluzenzakalelayo, izitimela ziqedela umsebenzi wokuthulula ngokuzenzakalelayo.Lapho isitimela singena esiteshini sokuthulula, isimiso sokulawula ukusebenza okuzenzakalelayo silawula isivinini sesitimela ukuze siqinisekise ukuthi isitimela sidlula emshinini othulula ujantshi ogobile ngesivinini esingaguquki ukuze kuqedelwe inqubo yokuthulula ngokuzenzakalelayo.Lapho uthulula, inqubo yokuhlanza nayo iqedwa ngokuzenzakalelayo.

Imisebenzi

Qaphela ukuthi akekho osebenza ohlelweni lokuthutha ujantshi ongaphansi komhlaba.

Bona ukusebenza kwesitimela okuzenzakalelayo futhi uthuthukise ukusebenza kahle kwesistimu.

Umphumela kanye nenzuzo yezomnotho

Imiphumela

(1) Ukuqeda izingozi zokuphepha ezingaba khona futhi wenze isitimela sihambe sibe sezingeni, sisebenze kahle futhi sizinze;

(2) Ukuthuthukisa ezokuthutha, ukukhiqiza okuzenzakalelayo kanye nezinga lokwaziswa, futhi kukhuthaze inqubekelaphambili yokuphatha kanye nenguquko;

(3) Thuthukisa indawo yokusebenza futhi uthuthukise ukusebenza kahle kokukhiqiza ezokuthutha.

Izinzuzo zomnotho

(1) Ngomklamo owenziwe kahle, thola ukulinganiswa kwensimbi okuphelele, unciphise inombolo yesitimela kanye nezindleko zokutshala izimali;

(2) Ukunciphisa izindleko zabasebenzi;

(3) Ukuthuthukisa ukusebenza kahle kwezokuthutha kanye nezinzuzo;

(4) Ukuqinisekisa izinga lensimbi elizinzile;

(5) Yehlisa ukusetshenziswa kwamandla ezitimeleni.